Sheet metal processing

Manufacturing process

KWM WEISSHAAR offers you comprehensive, state-of-the-art sheet metal processing. In addition to conventional manufacturing processes, we always use the latest technologies for processing steel, stainless steel, aluminum, copper and brass. Our high level of vertical integration gives us maximum flexibility. With an impressive machine park comprising a total of ten modern laser, punching and combination machines, we are ideally equipped to meet your production requirements.

Punch- and lasercenter

With an impressive range of machinery and modern laser, punching and combination machines, we are ideally equipped to meet your production requirements. In the field of 2D cutting, we have mastered the precise cutting of aluminum sheets up to a thickness of 15 mm, stainless steel sheets up to 25 mm and steel sheets up to 30 mm.

We rely on dedicated employees who ensure that your components are perfectly cut and prepared. In addition to our laser and punching machines, we have state-of-the-art machine combinations that offer optimum capacity, performance and flexibility.

Laser machinery

In the field of 3D cutting, our lasers are not only suitable for the precise cutting of materials and pipe processing, but also for high-quality laser welding. Our experts use the latest technologies and processes to provide you with the best results.

With us, you choose high-quality processing results, state-of-the-art technology and flexible production that adapts perfectly to your requirements. Don't hesitate to contact us and benefit from our many years of experience in metalworking.

Forming

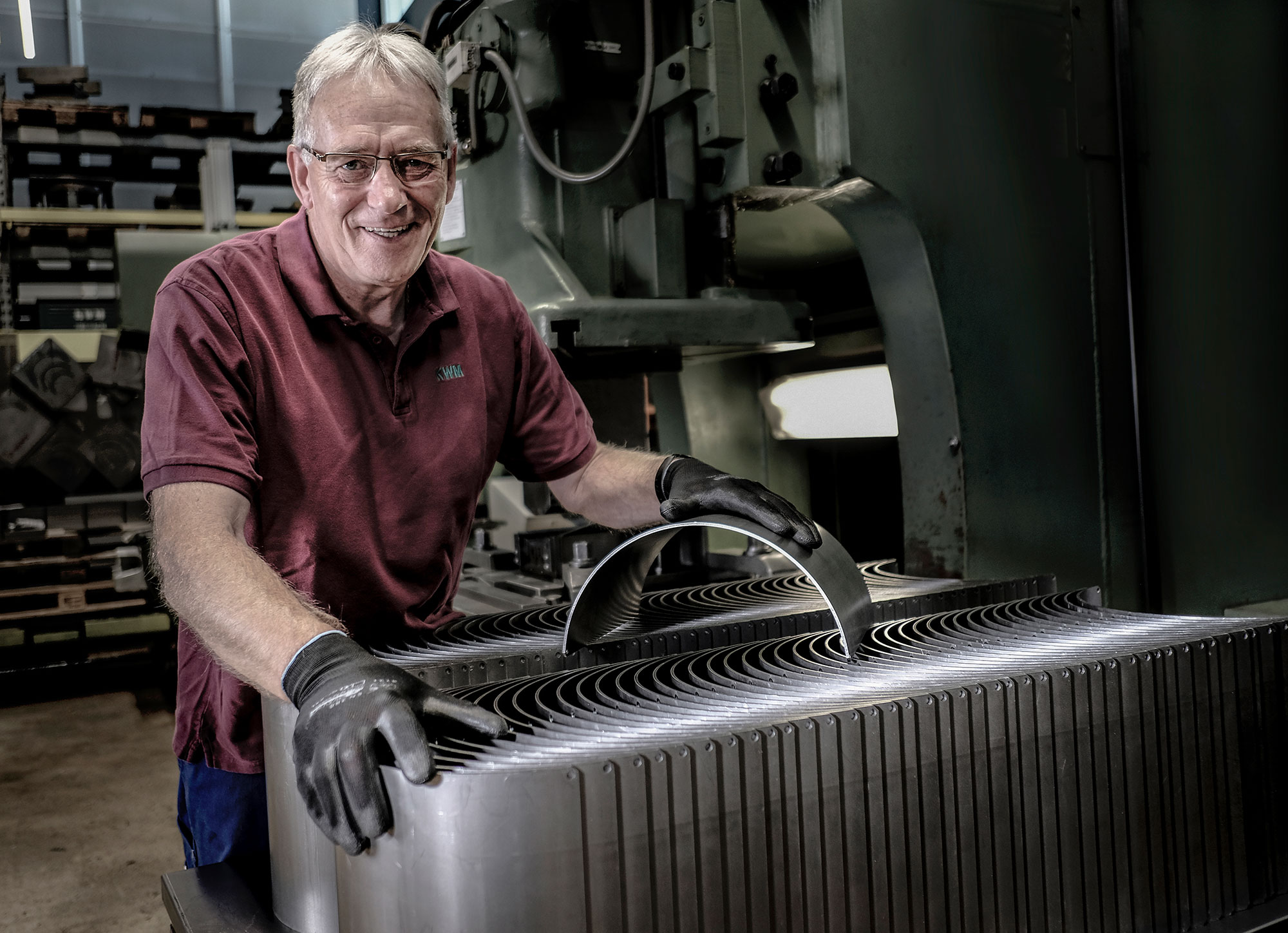

With a variety of presses capable up to 250 tonnes, a deep-drawing press with 315 tonnes press force and round and tube bending machines, we are extremely flexible to ensure versatile production.

Thanks to our modern equipment and experienced specialists, we are able to process large order volumes in the field of bending and punching production efficiently and precisely in order to fulfil our customers' needs.

Machining

In the area of profile processing, we are specialised in the precise processing of aluminium profiles with a length of up to 8 metres and a width of 1.5 metres. These components are primarily used in assemblies for interior fittings as well as in ceiling and air duct systems for railway vehicles.

We have also expanded our mechanical processing capacities in recent years. We have seven additional CNC drilling and milling centres at our disposal that can machine large parts.

Pipe production

In our pipe production, we offer the possibility of moulding different geometries. This includes various edge processing for cylindrical sheet metal hollow bodies such as beading, stepping, overlapping and flanging. We process various materials such as steel, stainless steel, aluminium, copper and brass and guarantee high quality and repeat accuracy, even for demanding forming operations. Our processes are extremely flexible and can be customised to meet our customers' individual requirements.