Bonding at KWM Weisshaar

Bonding in railway vehicle construction has developed into an innovative and versatile method over the last few decades. At KWM WEISSHAAR, we are proud to have a long history in the field of industrial bonding. Our journey began in 1985 in the printing machinery industry and since 1995 we have extended our expertise to rail vehicle construction. In 2006, we became one of the first 100 companies in Germany to be certified to DIN 6701 for bonding in rail vehicle construction. But why is bonding such an important and forward-looking technology?

The growing importance of bonding

Joining sheet metal by adhesive bonding not only enables strong force transmission, but also offers effective sealing, insulation and the use of a wide variety of materials. This versatility opens up new horizons in sheet metal processing and allows the combination of materials that were previously difficult to combine.

But what exactly are the advantages of adhesive bonding in rail vehicle construction and sheet metal processing?

Advantages of bonding

Force transmission: Bonding allows high loads to be transmitted without compromising the structure.

Sealing: Bonding ensures effective sealing, protects against moisture and environmental influences and increases the service life of vehicles and assemblies.

Insulation: Bonding makes it possible to insulate components, which enables better climate control and energy efficiency in rail vehicles.

Combination of many materials: Different materials such as metals, plastics and composites can be bonded together.

No distortion: Compared to welding, bonding minimises the distortion of components, which enables more precise production.

Corrosion protection: The bonded seam protects against corrosion, which extends the service life of vehicles.

Overall, adhesive solutions offer a wide range of benefits, particularly in terms of weight savings, reduced maintenance and increased efficiency. At KWM WEISSHAAR, we use our expertise and experience to develop customised adhesive solutions that meet the individual requirements of our customers.

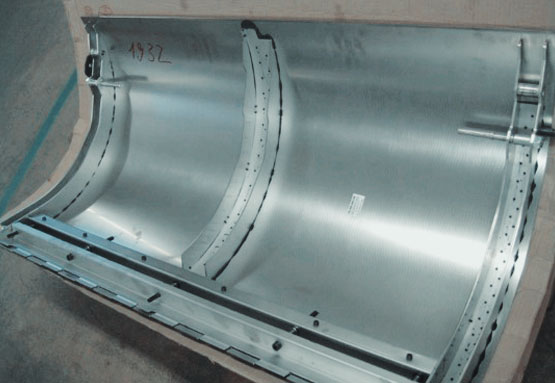

Before drilling

After bonding