2022

Acquisition of a fully automatic bending machine. The TruBend Cell 7000 now strengthens the team and can produce small and large series unmanned.

488 employees

2022

Acquisition of a fully automatic bending machine. The TruBend Cell 7000 now strengthens the team and can produce small and large series unmanned.

488 employees

Various investments, e.g. in a new 220 tonne 3-metre Amada press brake, a new Lissmac deburring and edge rounding machine.

485 employees

Investment in a new LECHNER 4-roll round bending machine 4160/110 and a new MAKA PM 270 CNC machining centre with 5-axis technology. A new 6KW fibre laser replaces one of our 5KW CO2 lasers.

499 employees

KWM WEISSHAAR is 40 years old. And this will be celebrated for two days with a customer day and an open day!

518 employees

Investment in a new lathe with driven tools that also runs in automatic mode, a new machining centre, a new Trumpf punching machine, renovation of our office buildings. Introduction of shop floor management.

501 employees

Our 10th trade fair presentation in Stuttgart was a complete success! The number of visitors was impressive. We are proud to present ourselves at trade fairs and introduce our innovative solutions to a wide audience.

487 employees

All production options and innovations as well as specialised lectures are presented at the Customer Technology Days.

501 employees

The decision has been made: ProALPHA will be the future ERP system. The first conversions from structura Nova to proALPHA are planned for 2017.

491 employees

Commissioning of another TruLaser Cell 7040 5-axis laser cutting and laser welding system for processing components up to 15 metres long.

508 employees

Commissioning of a new press brake for economical bending of small and medium batch sizes. Reconstruction of the pickling line.

510 employees

Successful re-certification in accordance with DIN 6701-2 (class A2) for bonding in railway vehicle construction. Exhibitor at InnoTrans in Berlin and for the first time at Swisstech in Basel.

501 employees

Commissioning of a further 3D laser system. Re-certification in accordance with DIN EN ISO 3834-2 and DIN EN 15085-2 CL1 for the welding of railway vehicles and vehicle parts.

510 employees

Re-certification according to DIN EN ISO 9001:2008. Commissioning of a blasting system with a steel grit cabin and a stainless steel blasting agent cabin. Investment in a further welding robot.

495 employees

Realisation of a new corporate design. Sheet metal process chain as new slogan. Anniversary days on the occasion of the 30th anniversary. Expansion of the IT infrastructure. Adhesive certification according to DIN 6701-2.

509 employees

Commissioning of the new punching/laser application centre, a high-bay honeycomb warehouse, a 110 kW photovoltaic system and three new machining centres. Construction of a large-scale welding shop. Move into the new office wing. Introduction of a new drawing management system.

530 employees

Company expansion from 33,400 m² to approx. 57,000 m². Reorganisation of the production areas to optimise the material flow with three additional production halls. Commissioning of a 2nd CNC milling machine in the aluminium profile processing area.

492 employees

Investment in a 6-axis measuring joint arm. Increase in production capacity with an additional punching machine, a CNC milling machine, a longitudinal seam welding machine and an orbital welding machine.

440 employees

Commissioning of a new 5 kW flat laser. A welding robot and a bending robot follow in the course of the year. Introduction of EDI, reorganisation of the logistics area.

415 employees

Completion and occupation of a 1,800 m² production and assembly hall. Start of aluminium profile processing up to 8,000 mm component length. Certification of our QM system according to DIN EN ISO 9001:2000.

407 employees

Commissioning of a Lauffer deep-drawing press (280 tonnes), spot welding machine using medium-frequency technology (300 kVA), Fasti round bending machine. Reconstruction of the stainless steel pickling plant (fully automatic process).

380 employees

Commissioning of a TRUMATIC 6000 punch-laser combination, TRUMATIC 5000 CNC punch with automatic material feed, 4-metre press brake and a four-roll round bending machine.

386 employees

Commissioning of a large paint shop, cleaning and degreasing system and CNC milling machine. Introduction of TOPLAS in the field of 3D laser programming and CATIA as an additional design platform.

377 employees

Completion and occupation of the seventh construction phase with an area of 2,900 m². Commissioning of the seventh laser system (6 kW).

387 employees

Start and completion of the 6th construction phase with the move into a second warehouse with a floor area of 1,620 m². Commissioning of the third machining centre.

338 employees

Expansion of assembly for railway technology and commissioning of the 6th laser system. 2D design now with CoCreate "ME10" and 3D design with CoCreate "Solid Designer".

341 employees

Expansion of production with social facilities, warehouse and administration area by 4,700 m², increase in machine capacity.

257 employees

Expansion in the areas of laser cutting, laser welding and tube cutting.

190 employees

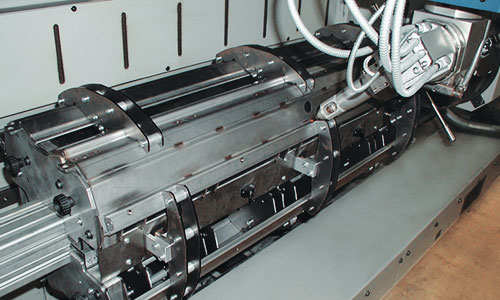

Entry into laser technology with a 5-axis laser cutting system. Design with CAD, HP ME 10 and ME 30.

189 employees

Expansion by 1,250 m² for production and work preparation.

158 employees

Expansion of the production area and social rooms to 7,000 m².

90 employees

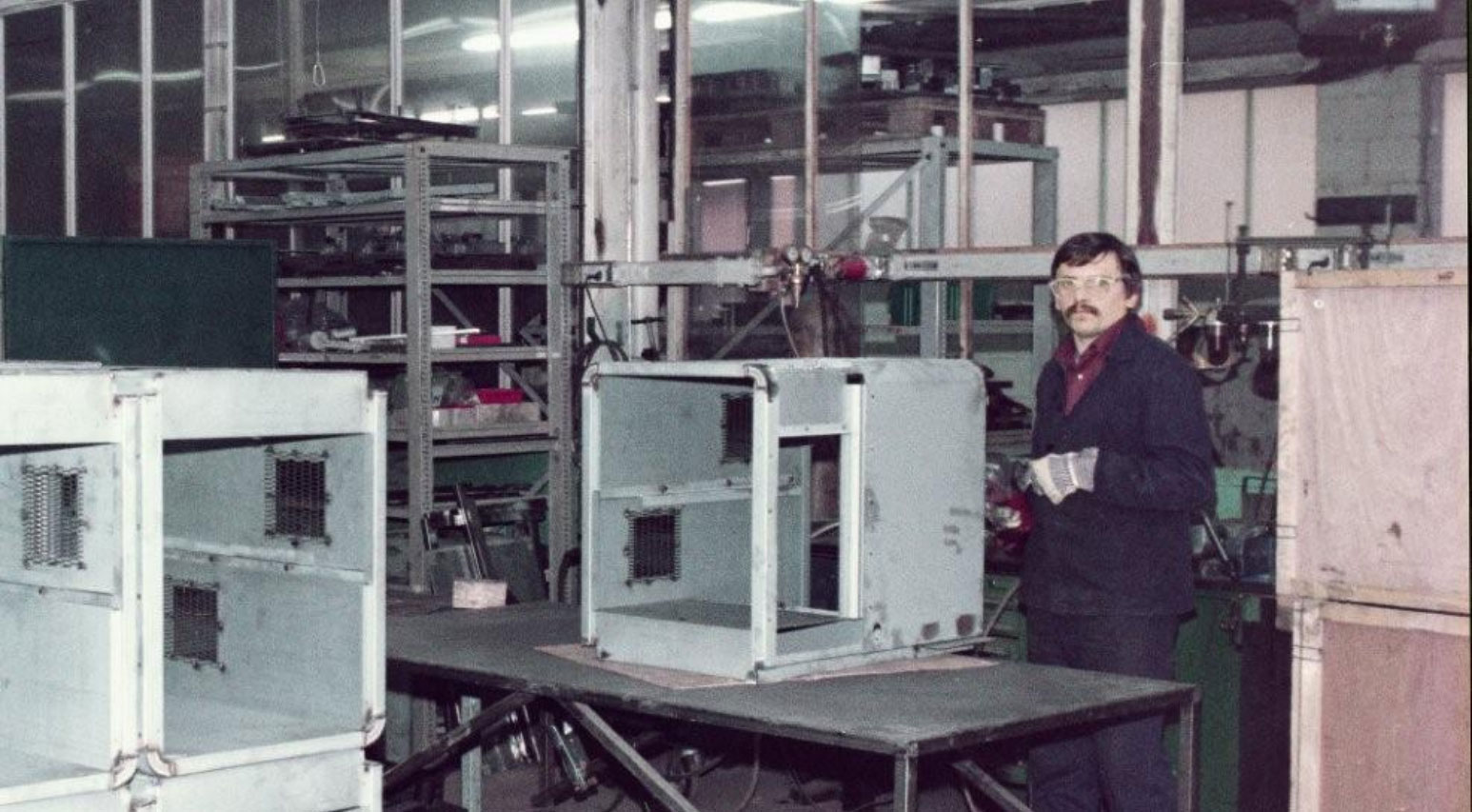

New factory building with a social and administration area of 3,500 m². Conversion of the sole proprietorship into KWM Weisshaar GmbH.

45 employees

Foundation

3 employees